Building Momentum on Mining Infrastructure Projects with 3D Scanning & SolidWorks Design

Mining infrastructure projects don’t fail because of ambition.

They stall because of uncertainty.

- Unclear existing conditions.

- Outdated drawings.

- Field changes not captured.

- Fabrication built to the wrong revision.

- Engineering decisions made on incomplete data.

If you want to build real momentum on a mining project — whether it’s a chute replacement, conveyor upgrade, pump skid, structural modification, or brownfield plant expansion — the first step isn’t modelling.

It’s truth.

At Hamilton By Design, we help mining operations build momentum from day one using engineering-grade 3D scanning and SolidWorks-based mechanical design workflows.

Below is how that momentum is created — and how it connects across our broader engineering services.

Step 1: Capture Reality – Engineering-Grade 3D Laser Scanning

Before SolidWorks modelling begins, we establish the true geometry of your site.

Using LiDAR and metrology-grade handheld scanning, we capture high-resolution point cloud data of:

Chutes and transfer stations

Conveyor structures

Pump skids

Steel platforms and accessways

Processing plant tie-ins

Underground or confined infrastructure

This ensures design decisions are based on what actually exists, not what the drawings say exists.

Learn more about our scanning capability:

👉 https://www.hamiltonbydesign.com.au/home/engineering-services/3d-laser-scanning/

For national capability and technical overview:

👉 https://www.hamiltonbydesign.com.au/engineering-grade-3d-laser-scanning-australia/

For digital QA workflows and validation:

👉 https://www.hamiltonbydesign.com.au/home/3d-lidar-scanning-digital-quality-assurance/

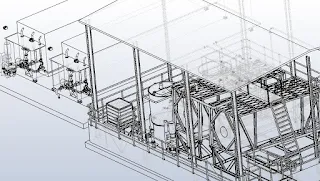

Step 2: Convert Data into Engineering Geometry

Point clouds are data.

Engineering requires geometry.

We convert scan data into structured, parametric SolidWorks models that allow:

Clash detection

Retrofit validation

Structural modification planning

Maintenance access assessment

Envelope clearance checks

Pre-fabrication certainty

This is where momentum builds.

Instead of “we think it will fit,”

you move to “we know it fits.”

Explore our mechanical design services:

👉 https://www.hamiltonbydesign.com.au/home/mechanical-engineering-consulting/mechanical-design/

Full mechanical engineering consulting capability:

👉 https://www.hamiltonbydesign.com.au/home/mechanical-engineering-consulting/

Step 3: Design for Mining Reality – Not Just CAD

Mining infrastructure is different.

Broken Hill, Mount Isa, Cobar, regional NSW — these are harsh operating environments with:

Abrasive ore streams

Constrained access

High maintenance loads

Legacy steelwork

Structural fatigue

Operational downtime pressure

Our mechanical design work in mining includes:

Chute and transfer redesign

Wear liner systems

Conveyor structure modifications

Pump skid integration

Structural steel certification

Crane runway inspections

Plant tie-in modelling

For regionally focused mining mechanical design:

👉 https://www.hamiltonbydesign.com.au/mechanical-design-consultants-broken-hill/

For mining-specific engineering services:

👉 https://www.hamiltonbydesign.com.au/home/engineering-services/mining-engineering-services-australia/engineering-led-lidar-mechanical-design-broken-hill/

Step 4: Build Maintenance into the Design

Momentum isn’t just about installation — it’s about lifecycle performance.

Too many mining projects deliver a new asset that becomes a maintenance headache.

At Hamilton By Design, we incorporate:

Safe liner change access

Scraper and wear component replacement zones

Guarding removal allowances

Tool clearance envelopes

Lifting lug positioning

Isolation planning

We design so your maintenance team can actually work on the asset.

If you’re upgrading chutes specifically:

👉 https://www.hamiltonbydesign.com.au/designing-chutes-for-easy-maintenance-the-hamilton-by-design-approach/

Step 5: Governance – Protecting Momentum

Nothing destroys momentum like:

Fabrication to the wrong revision

Uncontrolled drawing updates

Unclear document ownership

Poor digital traceability

We don’t just design.

We implement engineering governance.

Through structured CAD management and revision control systems, we ensure:

Every issued drawing is traceable

Revision history is controlled

Clients have 24/7 access to their documentation

Field changes are captured and managed

ISO-aligned document control can be established

Learn more about our engineering governance approach:

👉 https://www.hamiltonbydesign.com.au/engineering-governance-24-7-drawing-access-fea/

Step 6: Integrating Scanning with SolidWorks FEA

Momentum means reducing risk early.

When we combine:

3D scanning

Parametric modelling

Finite Element Analysis

We can validate:

Structural load paths

Wear plate stress

Crane runway modifications

Pump skid dynamic loads

Support frame adequacy

This allows engineering decisions to be made confidently before steel is cut.

You’re not reacting to site issues.

You’re preventing them.

Brownfield Mining Projects: Where Momentum Matters Most

Greenfield projects have clean drawings.

Brownfield mining projects have surprises.

3D scanning + SolidWorks modelling allows:

Accurate tie-ins to legacy structures

Retrofit without rework

Pre-fabrication off-site with confidence

Reduced shutdown duration

Fewer RFIs during installation

For operations across Australia needing scanning support:

👉 https://www.hamiltonbydesign.com.au/home/engineering-services/3d-laser-scanning/

For Melbourne-based engineering support:

👉 https://www.hamiltonbydesign.com.au/3d-scanning-melbourne-cbd/3d-engineering-in-melbourne/3d-scanning-services-in-melbourne/

What Building Momentum Actually Looks Like

When momentum is working, you see:

Faster approvals

Clearer scope definition

Fewer variations

Confident procurement

Reduced shutdown windows

Safer installation

Maintenance-ready assets

It starts with clarity.

It builds with engineering structure.

It accelerates with correct data.

Why Mining Clients Choose Hamilton By Design

We combine:

Site experience in heavy industry

Engineering-grade scanning

SolidWorks mechanical design

Mining infrastructure familiarity

Governance discipline

Regional mining knowledge

We don’t just produce drawings.

We help mining infrastructure projects move from:

Uncertain → Verified

Reactive → Planned

Concept → Installed

Installed → Maintainable

And that is how momentum is built.

Ready to Build Momentum on Your Mining Project?

If your project is stalled due to:

Unclear geometry

Legacy plant constraints

Retrofit risk

Documentation gaps

Design uncertainty

Start with scanning.

Start with clarity.

Start with structured engineering.

Explore Hamilton By Design:

👉 https://www.hamiltonbydesign.com.au/

Or contact us to discuss your mining infrastructure project and how 3D scanning and SolidWorks design can accelerate delivery.